how to test a circuit breaker

Testing a circuit breaker is crucial to ensure its proper operation, safety, and reliability. The following methods cover low-voltage (LV), medium-voltage (MV), and high-voltage (HV) circuit breakers.

1. Visual & Mechanical Inspection

Before electrical testing, perform these checks:

✔ Physical condition (damage, corrosion, alignment).

✔ Tightness of connections (bolts, terminals).

✔ Mechanical operation (manual & automatic opening/closing).

✔ Lubrication & moving parts (hinges, springs).

✔ Arc chutes & contacts (wear, pitting, contamination).

2. Electrical Tests

A) Insulation Resistance Test (Megger Test)

Purpose: Checks insulation integrity (phase-to-phase & phase-to-ground).

Test Voltage:

LV Breakers (≤1kV): 500V or 1000V DC.

MV/HV Breakers (≥1kV): 2.5kV to 5kV DC.

Acceptance Criteria:

LV: >1 MΩ (minimum).

MV/HV: >100 MΩ (or per manufacturer specs).

B) Contact Resistance Test (Micro-Ohmmeter)

Purpose: Detects high-resistance contacts (wear, oxidation).

Test Method: Apply DC current (100A or more) and measure voltage drop.

Acceptance Criteria:

LV Breakers: <50 μΩ (typical).

MV/HV Breakers: <100 μΩ (varies by type).

C) Timing Tests (Open/Close Time, Synchronization)

Purpose: Ensures proper opening/closing speed.

Equipment: Circuit breaker analyzer.

Key Parameters:

Opening Time: Typically 20–50 ms (HV breakers).

Closing Time: Should match manufacturer specs.

Contact Wipe & Bounce: Should be minimal.

D) Dielectric (Hi-Pot) Test

Purpose: Verifies insulation strength.

Test Voltage:

LV: 2 × Rated Voltage + 1kV (e.g., 480V breaker → ~2kV).

MV/HV: As per IEEE/IEC standards (e.g., 36kV breaker → 70kV AC for 1 min).

Caution: Do not exceed manufacturer limits (risk of insulation damage).

E) Trip Unit Testing (For LV/MV Breakers with Relays)

Primary Injection Test:

Injects high current (up to breaker rating) to verify trip settings.

Checks instantaneous, short-time, and long-time tripping.

Secondary Injection Test:

Simulates fault current via relay test set.

Verifies protection settings (e.g., 0.5s delay at 5× rated current).

F) Dynamic Contact Resistance (DCRM) – For HV Breakers

Measures resistance during operation to detect arcing wear.

3. Special Tests (For Critical Applications)

A) Partial Discharge (PD) Test

Detects insulation defects in MV/HV breakers.

Acceptance: PD levels <10 pC (typical).

B) X-ray or Ultrasound Inspection

Checks internal mechanical alignment without disassembly.

C) SF₆ Gas Analysis (For Gas-Insulated Breakers)

Measures moisture, purity, and decomposition products (SO₂, HF).

4. Functional Tests (Before Re-energization)

✔ Manual & Remote Operation (close/open via control panel).

✔ Alarm & Indication Checks (trip signals, spring charge status).

✔ Interlock Verification (prevent unsafe operations).

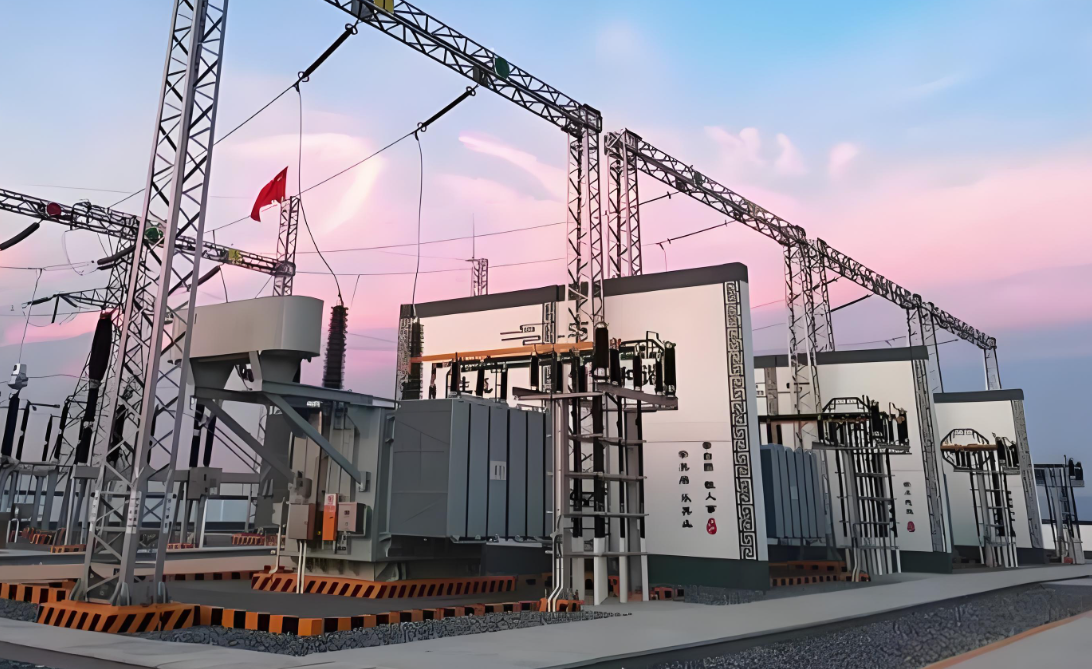

The above content is published by demiks, please specify, demiks is a substation equipment manufacturer, specializing in the production of high-voltage tester, transformer test equipment, circuit breaker test equipment, relay tester, SF6 gas analyser, cable fault tester and other products, if you have power test testing needs, please feel free to contact demiks power science and technology limited company or send an email! Give us: contact@demikspower.com

Relay Protection Testing and Commissioning Gu

Relay Protection Testing and Commissioning Gu

how to test microwave transformer

how to test microwave transformer

how to reset circuit breaker with test button

how to reset circuit breaker with test button

high voltage cable testing standards

high voltage cable testing standards