Relay Protection Testing and Commissioning Guide

Protection Relay Testing & Commissioning Guide

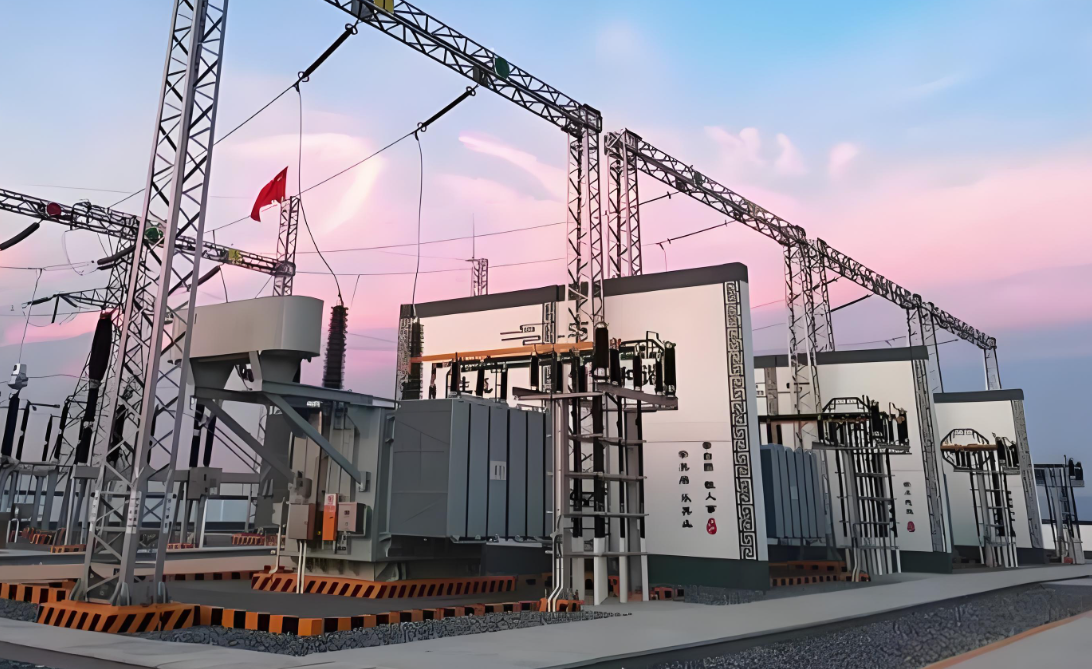

Protection relays are critical for safeguarding electrical systems against faults (overcurrent, earth faults, differential, etc.). Proper testing and commissioning ensure reliability and compliance with standards like IEC 60255, IEEE C37.90, and ANSI/IEEE standards.

1. Pre-Commissioning Checks

Before testing, verify:

Visual Inspection – No physical damage, loose connections, or burnt components.

Wiring & CT/PT Connections – Correct polarity, ratio, and grounding.

Settings Verification – Relay settings match the protection scheme (IDMT curves, pickup values, time delays).

Secondary Injection Test Kit – Ensure availability for relay testing.

2. Types of Protection Relay Tests

A. Static (Functional) Tests

Performed to verify relay logic and settings without tripping the actual circuit.

1. Secondary Injection Test

Injects test currents/voltages directly into relay terminals.

Tests: Pickup, timing, overcurrent, earth fault, differential, distance protection.

Equipment: Omicron, Megger, or manual test kit.

2. Measurement Accuracy Test

Checks if relay measures current (I), voltage (V), power (P, Q), frequency (Hz) correctly.

Method: Apply known values and compare with relay readings.

3. Logic & Scheme Testing

Verifies tripping, alarm, and communication signals (GOOSE, IEC 61850).

Example: Test a differential relay by unbalancing CT inputs.

B. Dynamic (System) Tests

Validates relay behavior under real-world conditions.

1. Primary Injection Test

Injects high current (up to rated CT value) to test the full protection chain (CT → relay → breaker).

Purpose: Ensures CT polarity, ratio, and relay coordination.

2. End-to-End Testing (Distance Protection)

Simulates faults at different line locations to check zone tripping times.

Requires communication-assisted schemes (POTT, DUTT).

3. Breaker Trip Test

Verifies relay commands actually trip the breaker.

Method: Trigger relay manually and check breaker operation.

3. Commissioning Procedure

Step 1: Relay Settings Verification

Confirm settings match protection coordination study.

Check:

Pickup values (e.g., 50/51 – Overcurrent)

Time delays (IDMT curves)

Blocking & Alarm signals

Step 2: Secondary Injection Tests

Overcurrent (50/51) Test

Inject 1.05 × pickup current → Relay should operate.

Verify time delay matches the curve (NI, EI, VI).

Earth Fault (50N/51N) Test

Inject residual current (I₀) and check tripping.

Differential (87) Test

Simulate internal & external faults to verify stability.

Distance (21) Test

Test Zone 1 (80% reach), Zone 2 (120%), Zone 3 (backup).

Step 3: Primary Injection & System Tests

Confirm CT/PT wiring correctness.

Perform fault simulation (phase-phase, phase-earth).

Step 4: Final Documentation & Sign-Off

Record test results in test sheets.

Update relay settings files and as-built drawings.

4. Common Issues & Troubleshooting

Relay Fails to Trip

Check CT polarity, relay settings, control circuit.

False TrippingVerify stability (differential relays), harmonics blocking.

Communication Failures (IEC 61850)Check GOOSE/SV messages, network configuration.

5. Standards & Best Practices

IEC 60255 (Protection relay standards)

IEEE C37.90 (Relay withstand capabilities)

ANSI C37.90.1 (Surge immunity)

NFPA 70E (Electrical safety during testing)

Conclusion

Proper protection relay testing & commissioning ensures system reliability and prevents catastrophic failures. Always follow safety procedures and use calibrated test equipment.

The above content is published by demiks, please specify, demiks is a substation equipment manufacturer, specializing in the production of high-voltage tester, transformer tester, circuit breaker test equipment, relay tester, SF6 gas analyser, cable fault tester and other products, if you have power test testing needs, please feel free to contact demiks power science and technology limited company or send an email! Give us: contact@demikspower.com

Relay Protection Testing and Commissioning Gu

Relay Protection Testing and Commissioning Gu

how to test microwave transformer

how to test microwave transformer

how to reset circuit breaker with test button

how to reset circuit breaker with test button

high voltage cable testing standards

high voltage cable testing standards